Sea Freight in Containers

Containerized sea freight represents an increasingly growing volume in our country's foreign trade.

More and more companies export and import using multimodal shipping methods from overseas. The number of domestic shipping companies and carriers is growing, confirming this trend. The share of overseas foreign trade in our total trade amounts to 13-15%, with 4260 billion HUF in turnover in 2006. Of this, 30% was export.

Sea Freight with Containers

Sea freight is a highly complex process, involving multiple participants whose coordinated and precise work is essential.

The selection of the appropriate container for the shipment requires specialized knowledge, not to mention the handling of ocean-going vessels and their impressive machinery, capable of carrying up to 9000 TEUs on a single journey.

TEU

[Twenty-foot equivalent unit]

20-feet

[Standard steel container]

The documentation of the whole transport process, the contract between the carrier and the shipper, the bill of lading and a thorough and up-to-date knowledge of international maritime law can save a prospective exporter or importer a lot of hassle.

Intermodal Logistics

The case of combined transportation

In the case of combined transportation, we would like to mention the railway operator companies and the routes operated by them, which allow a container to travel from Hamburg to Budapest in just 22 hours. However, this would not be possible without the development of local Logistics Service Centers.

The Truck Driver Who Revolutionized Shipping

Malcom P. McLean, an American businessman, who is also called the father of containerization, started his career as a truck driver.

McLean’s innovation lay in the fact that containers were not restricted to just the paths between the shipper and the destination, and he ensured compatibility with various transport equipment by standardizing container sizes. At the beginning, he even loaded entire trucks onto ships to bring them closer to their final unloading locations.

McLean rationalized the transport of goods by minimizing the time and financial costs of loading and unloading in the case of different transport equipment.

Development of Containerized Freight Transport

- MALCOM P. MCLEAN

Containerisation

The standardization of road transport vehicles and container sizes and their rapid development made it possible for containers to first be loaded onto trucks, and later to be transported without the need for additional framing onto ships.

This saved space and reduced costs. The next step was that the containers were left behind, with only the container itself being loaded onto the ships.

- MALCOM P. MCLEAN

Founding of Sea-Land

At first, ship owners were skeptical about McLean’s idea, so he bought his own ships.

He founded Sea-Land Shipping in 1960. In 1989, McLean sold the company to Maersk Line, and the company continued to operate under the name Maersk Sealand.

- MALCOM P. MCLEAN

Global Cargo Transport with Containers

The first containerized ship was called Ideal-X. On April 26, 1956, the ship left Newark Port with 58 containers on its deck, with its destination being Houston.

Among the first containerized ships was the Maxton, which was a converted tanker capable of carrying 60 containers on its deck. It took ten years to cross the Atlantic and dock at European ports as the first containerized ships arrived at European ports. A Fairland ship in 1966 docked at the Bremerhaven port. The first containers used were 35 ASA type containers (American standard). Since then, 27-foot containers are still in use.

European and Japanese ship owners quickly recognized the advantages of containerized transport and were eager to invest in this new business. Since American standards only applied to large ships, there were significant challenges in Europe, especially in Japan, where standardization had to be done to apply the standards. The solution was the introduction of ISO standards, which set the sizes of containers at 10, 20, 30, and 40 feet long, 8 feet wide, 8.6 feet high.

ISO Sea Containers

For European road transport, containers with a width of 2.5 meters were standardized.

This width is also used in combined transport. The majority of containers currently in use conform to ISO standards. The most common are 20 and 40-foot containers, and 40-foot Highcube types. In recent years, the pressure has increased because storage and transport have become the main cost factors, so transporters are looking for even wider and longer containers.

Extra Size Containers

Some shipowners have allowed for the use of Jumbo containers, which are 45 and 48 feet long, with widths of 8.6 feet (2.60 meters) and heights of 9.6 feet (2.90 meters). In fact, in some states of America, containers of 53 and 57 feet long are commonly used.

Jumbo

[45 and 48 feet available]

America

[53 and 57 feet available in certain states]

Fast quote within 1 day

Request a quote for container purchase or rental in just a few minutes by filling out the form below!

info@container.hu

+36 1 200 8703

+36 20 365 4330

+36 30 609 8092

+36 20 262 5173

2030 Érd, Fiastyúk Street 7, at the junction of the M6 highway and the main roads 6 and 7.

Please note that installment and leasing options are primarily available to companies based on the Opten company evaluation.

Flow of Sea Storage Containers

The capital and efforts invested in containerization have paid off, as container traffic continues to grow.

Naturally, every growth has its limit. According to cautious estimates, the maximum container traffic capacity would correspond to about 8000 ships in operation, carrying 6 million or 10 million standard container slots. From the perspective of container shipping, it would be ideal to have a balanced flow of containers arriving and departing in each region. Unfortunately, achieving such equilibrium is not likely to be realized anytime soon.

Global Logistics Challenges

The use of accumulated empty containers is unavoidable.

- This phenomenon can be observed in the European and Asian trade routes, where the continually growing export container demand cannot be met by the imported container volumes from Europe.

- Hungary also has an import-export ratio of 70-30%, meaning that about half of the containers arriving here have to be shipped empty back to Asia.

Shipping Companies and Transportation Costs

From the perspective of shipping companies, it would be most advantageous if most goods were loaded into standard 20-foot and 40-foot containers, and 40-foot HC containers for shipment. The shipping companies would prefer to load these containers, as they carry more cargo compared to the standard ones. Due to transportation costs, shipping companies often use flexitank containers in normal box containers to transport.

Classification of Containers

According ISO

- Transportation aids that have at least 1m³ capacity.

- Equipped with loading devices (corner fittings) that enable easy movement and transfer to different transport equipment.

- They make it possible to transport goods with various types of transport equipment.

- Goods can be transported without additional handling, making them durable and resistant to external environmental influences.

Based on size

- Small containers: Cargo capacity of 1–3 m³, usually equipped with wheels and securing devices. These containers are not used in domestic rail and road transport but are common in international transport.

- Medium containers: At least 3 m³ capacity, usually 6 meters long. They can be lifted by cranes or other specialized equipment using a four-cornered base. 10-foot containers are the most commonly used.

Functionality

- Box container: Completely sealed, with a door that can be opened at one end. The most commonly used types in shipping are 20 feet, 40 feet, and 40 feet HC (High Cube). The 40 feet HC container is 1 foot higher than a standard 40 feet container.

- Open-top container: The container has an open top that can be covered with a tarpaulin. These are primarily used for transporting large heavy loads that can be loaded from the top into the container. The container types available are 20 feet and 40 feet.

Ownership

- Railway-owned container: can only be used for railway freight transport, not suitable for maritime transport.

- Container owned by leasing companies: can be leased under specific conditions.

- Container owned by shipping companies: Most containers fall into this category. They are generally used by the shipping companies, but it is possible for them to lease space on their ships.

Marking and Numbering of Storage Containers

The marking and identification of containers is done based on the DEN EN ISO 6346 standard. A distinction must be made between mandatory and optional markings. According to ISO, mandatory markings must be displayed on all containers.

The container number consists of 11 characters.

This abbreviation must be registered with BIC.

The fourth character is always the English word 'UNIT.'

The next 6 characters are numbers.

The Last Character

The 11th and final character is the check digit, which can be determined based on the following:

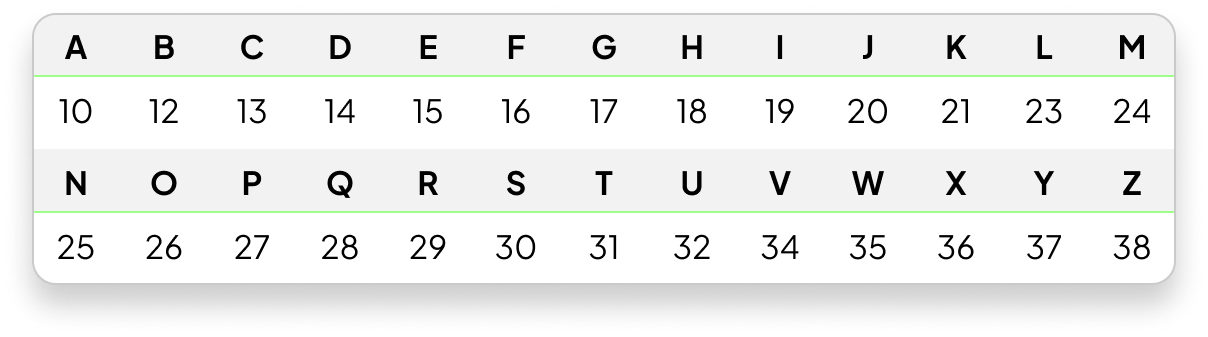

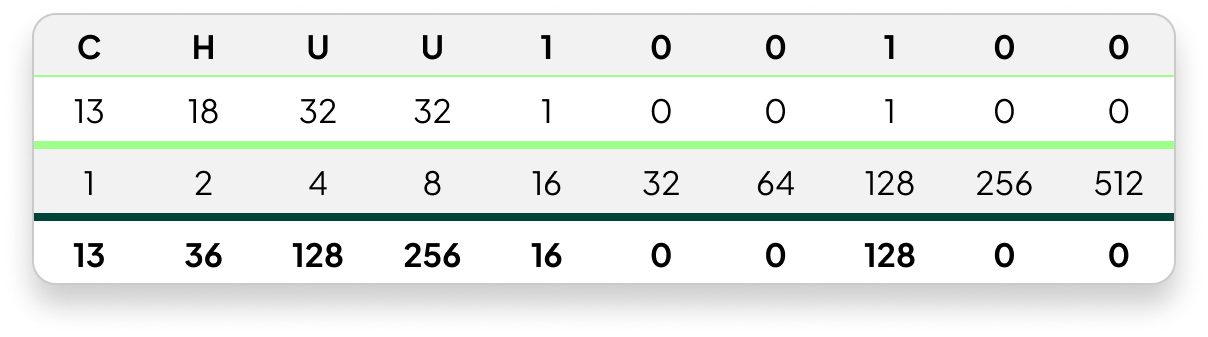

We assign a number to each letter of the alphabet.

[11 and multiples are omitted]

The next 6 characters maintain their values.

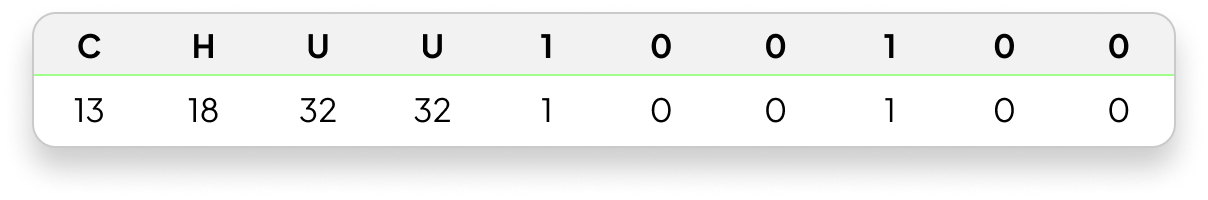

A CHUU 100100-hoz tartozó számsor

We multiply these 10 numbers by the powers of 2

[1, 2, 4, 8, 16, 32, 64, 128, 256, 512, …]

The sum of these numbers is 577, which is divided by 11, resulting in 52,45454545. I multiply the whole part by 11, which is 572. The difference between the resulting number 572 and the value between 577 gives the last number: 5.

The final check digit is 5.

Placement of Identification Numbers

The container numbers are placed according to the orderer’s request, typically on the door, the two sides, the rear wall, and the roof. They are painted from the outside, and the first corner casting is also stamped.